Understanding Pixel Density in SMD Screens: What You Need to Know

In the ever-evolving world of display technology, understanding the intricacies of pixel density in SMD (Surface-Mount Device) screens is crucial. Whether you’re a seasoned professional or new to the field, comprehending the finer details of pixel density can greatly influence the visual quality and clarity of your screens. This article aims to provide an in-depth insight into the significance of pixel density in SMD screens, shedding light on its importance and equipping you with the knowledge to make informed decisions in your display projects. By delving into the technical aspects and discussing key considerations, we invite you to explore the world of pixel density and uncover the essentials you need to know when working with SMD screens.

Table of Contents

- Understanding Pixel Density: The Key to High-Quality SMD Screens

- Demystifying Pixel Density: How it Impacts Display Performance

- The Benefits of Optimal Pixel Density in SMD Screens

- Choosing the Right Pixel Density: Recommendations for Optimum Display Efficiency

- Q&A

- To Conclude

Understanding Pixel Density in SMD Screens: The Key to High-Quality SMD Screens

One of the key factors in determining the quality of SMD screens is their pixel density. Pixel density refers to the number of pixels per unit area of the screen. In simpler terms, it measures the level of detail and clarity you can expect from a screen. Understanding pixel density is crucial for anyone looking to invest in high-quality SMD screens, as it directly impacts the viewing experience.

When it comes to pixel density, higher is usually better. A higher pixel density means more pixels are packed into a smaller area, resulting in a clearer and sharper image. This is particularly important for screens that are viewed up close, such as those used in indoor displays or video walls. With a higher pixel density, you can ensure that every detail is captured and displayed accurately, making the content more immersive and engaging for the audience.

To further illustrate the importance of pixel density, let’s take a look at an example. Imagine two screens with the same dimensions, but different pixel densities. Screen A has a pixel density of 100 pixels per inch (PPI), while Screen B has a pixel density of 200 PPI. When viewing a high-resolution image on both screens, you will notice that the image on Screen B appears much sharper and more detailed compared to Screen A. This is because the higher pixel density on Screen B allows for a greater level of detail to be displayed.

In conclusion, understanding pixel density is crucial for anyone looking to invest in high-quality SMD screens. By opting for screens with higher pixel densities, you can ensure that your content is displayed with exceptional detail and clarity. Whether you’re setting up an indoor display or a video wall, the pixel density of your SMD screens will play a significant role in delivering an immersive viewing experience.

Demystifying Pixel Density in SMD Screens: How it Impacts Display Performance

Pixel density is a crucial aspect to consider when evaluating the performance of SMD screens. It refers to the number of pixels per inch (PPI) on a display, and it plays a significant role in determining the level of detail and image quality that can be achieved. Higher pixel densities result in sharper and more vibrant visuals, while lower densities may lead to pixelation and a loss of clarity.

When choosing an SMD screen, it’s important to understand how pixel density impacts display performance. A higher pixel density allows for more detail to be displayed, resulting in a clearer and more lifelike image. This is particularly important when it comes to large displays or screens that will be viewed up close, such as those used in advertising or entertainment venues.

To better understand the impact of pixel density, let’s take a look at an example. Imagine two SMD screens with the same resolution but different pixel densities. Screen A has a lower pixel density of 100 PPI, while Screen B boasts a higher density of 200 PPI. When viewing an image on Screen B, the pixels are much smaller and closer together, resulting in a crisper image. On the other hand, Screen A may show noticeable pixelation due to the larger and more spread-out pixels.

In summary, pixel density greatly influences the visual quality of SMD screens. It’s crucial to choose a display with an appropriate pixel density based on the purpose and viewing distance. Understanding this concept allows for informed decision-making when selecting the right SMD screen for your specific needs.

The Benefits of Optimal Pixel Density in SMD Screens

With the rapid advancement of technology, SMD (Surface Mount Device) screens have become increasingly popular in various industries. One of the key factors to consider in SMD screens is pixel density. Pixel density refers to the number of pixels per unit area on a screen and plays a crucial role in determining the clarity and details of displayed content. Understanding is essential for users and businesses alike.

- Enhanced Visual Experience:

- Optimal pixel density ensures sharper and more vibrant images, resulting in a rich and immersive visual experience.

- Higher pixel density allows for greater detail, making text, graphics, and videos appear crisp and lifelike.

- The ability to display more pixels within a confined area can create seamless imagery, providing viewers with a visually appealing display.

- Improved Content Delivery:

- Optimal pixel density in SMD screens allows for the effective delivery of high-resolution content, which is particularly crucial for industries such as advertising and digital signage.

- Higher pixel density facilitates the showcase of intricate details in images and videos, ensuring that the intended message is accurately communicated to the target audience.

- With enhanced sharpness and clarity, SMD screens with optimal pixel density can captivate viewers and effectively convey information, resulting in better engagement and interest.

In conclusion, having optimal pixel density in SMD screens offers numerous benefits, ranging from an enhanced visual experience to improved content delivery. By investing in SMD screens with the ideal pixel density, businesses can effectively communicate their message, boost customer engagement, and stay ahead in today’s competitive market.

Choosing the Right Pixel Density in SMD Screens: Recommendations for Optimum Display Efficiency

Choosing the right pixel density for your SMD screen is crucial to ensure optimum display efficiency. But with so many options available, it can be overwhelming to determine the best choice. In this article, we will provide you with recommendations to help you make an informed decision.

Consider the Viewing Distance: One of the key factors in selecting pixel density is the viewing distance. The closer the audience will be to the screen, the higher the pixel density required. This ensures that the content appears sharp and clear, without any pixelation. For indoor environments with a short viewing distance, a high pixel density of at least 3mm is recommended. On the other hand, for large outdoor displays with viewers at a distance, a lower pixel density of 10mm or more may be sufficient.

Assess the Content: Different types of content have varying pixel density requirements. If your display will primarily showcase high-resolution images or videos, a higher pixel density is essential to maintain the quality of the visuals. However, if your content consists mainly of text or simple graphics, a lower pixel density can still deliver a satisfactory viewing experience. By considering the type of content you will be displaying, you can determine the appropriate pixel density for your SMD screen.

Q&A

Q: What is pixel density in SMD screens?

A: Pixel density refers to the number of pixels per unit of screen space in a surface-mount device (SMD) screen. It indicates how closely packed the individual pixels are, influencing the level of detail and clarity in the displayed content.

Q: How is pixel density measured?

A: Pixel density is generally measured in pixels per inch (PPI) or dots per inch (DPI). The higher the PPI or DPI, the smaller the pixels and the greater the detail that can be displayed on the screen.

Q: Why is pixel density important?

A: Pixel density directly affects the visual quality and sharpness of the displayed content. Higher pixel density allows for greater clarity, finer details, and smoother image reproduction. It enhances the viewing experience and is particularly crucial for screens used in applications that demand high resolution and clarity, such as digital signage, video walls, and large-scale screens.

Q: How does pixel density impact image quality?

A: A higher pixel density ensures that individual pixels are indistinguishable to the human eye, resulting in sharper images with better color accuracy and contrast. With a lower pixel density, the individual pixels become more visible and can lead to blocky or pixelated images.

Q: What are some benefits of screens with higher pixel density?

A: Screens with higher pixel density can deliver more lifelike and immersive visual experiences. They enable users to view content from a closer distance without any loss in image quality, allowing for larger screens in confined spaces. Increased pixel density is also beneficial for text-based content, where sharpness and legibility are essential.

Q: Are there any limitations or challenges with high pixel density screens?

A: High pixel density screens require more processing power to render the finer details, which can impact performance if the hardware is not capable. Additionally, higher pixel density screens can consume more power, affecting battery life in portable devices.

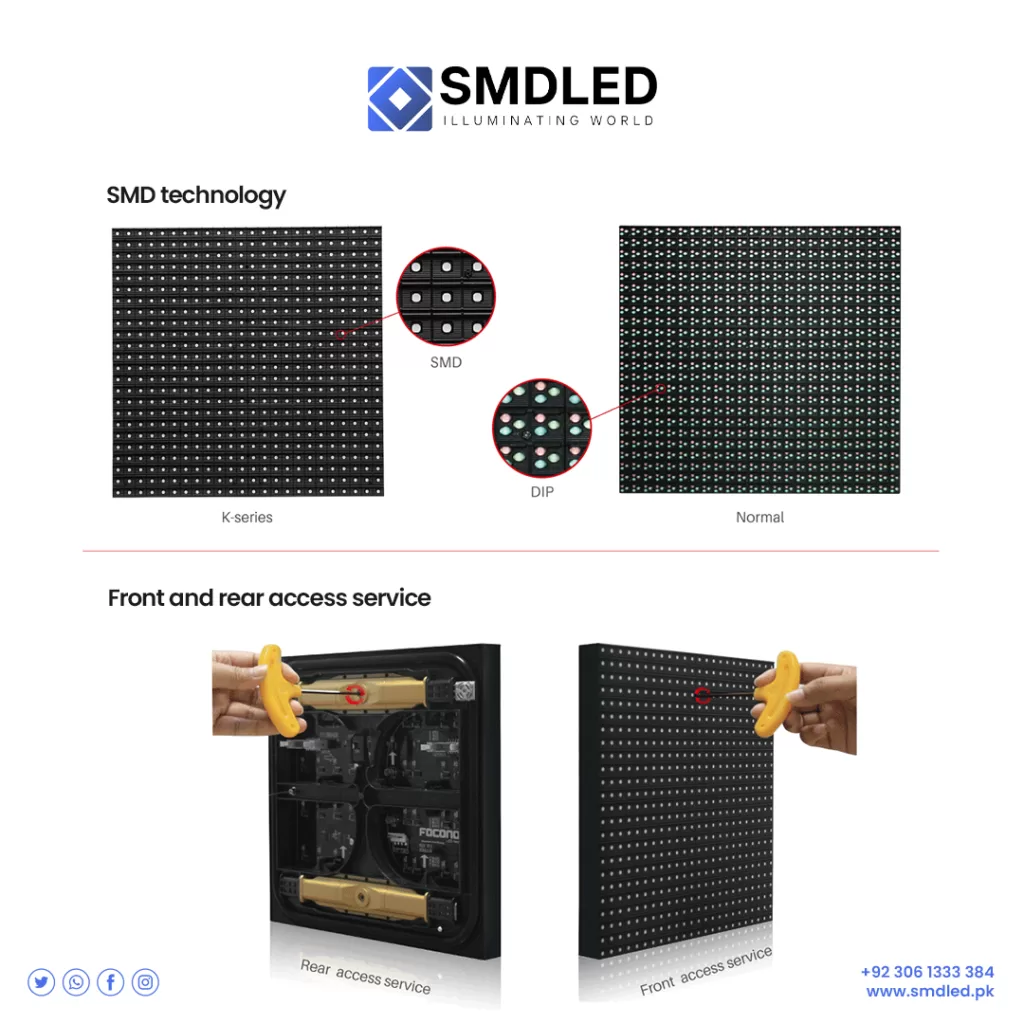

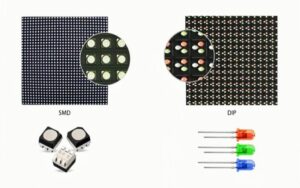

Q: How does pixel density differ between various SMD screen technologies?

A: Pixel density varies depending on the screen technology employed. For instance, organic light-emitting diode (OLED) screens generally have a higher pixel density compared to traditional liquid crystal displays (LCDs). However, advancements in LCD technology have enabled the production of high-resolution screens with competitive pixel densities.

Q: Is there an optimal pixel density for all applications?

A: The optimal pixel density depends on the specific application and viewing distance. For instance, screens viewed up close, such as mobile devices or virtual reality headsets, benefit from higher pixel densities. In contrast, screens used in large-scale applications, like outdoor billboards viewed from a distance, may have lower pixel densities due to the limited viewing distance.

Q: How can one determine the appropriate pixel density for their application?

A: Determining the appropriate pixel density involves considering the viewing distance, desired image quality, and the available budget. Consulting with industry professionals or screen manufacturers can help in identifying the ideal pixel density for a specific application.

Q: Are there any future developments in pixel density technology?

A: As technology advances, there is a continuous push to improve pixel density. Manufacturers are exploring new techniques like miniaturization, subpixel rendering, and increased display resolution to achieve higher pixel densities in future screens. These developments aim to provide consumers with even more vibrant and detailed visual experiences.

To Conclude

In conclusion, understanding pixel density in SMD screens is crucial for achieving optimal visual clarity and image quality. By grasping the concept of pixel density and its significance in relation to screen size, viewing distance, and resolution, you can make informed decisions when selecting SMD screens for your business or personal use.

We have explored the definition of pixel density and how it is calculated, shedding light on why a higher pixel density is preferred for screens that are viewed up close. We have also discussed the impact of pixel density on image sharpness, color accuracy, and overall viewing experience.

Moreover, considering the factors influencing pixel density, such as screen size and resolution, is vital in ensuring the right SMD screen is chosen for a particular application. While larger screens with higher resolutions tend to offer higher pixel densities, one must strike a balance between pixel density and viewing distance to avoid unnecessary costs or compromised viewing experiences.

It is essential to note that pixel density alone does not determine the quality of an SMD screen. Other aspects, including panel technology, refresh rate, and color reproduction, should also be considered when making a decision.

As technology continues to advance and display resolutions increase, it is important to stay informed about pixel density and its implications. With this knowledge, you can confidently engage in discussions and make informed choices when it comes to SMD screens, ensuring that the visual experience meets your expectations and requirements.

In the ever-evolving world of display technology, grasping the concept of pixel density is an invaluable tool, enabling you to unlock the true potential of SMD screens and enjoy vibrant, crisp, and detailed visual content.

Looking for premium SMD screens and professional display solutions? SMDLED.PK is your trusted partner for state-of-the-art SMD technology. Explore our top-quality products like the stunning Leyard HDR 4K SMD Video Wall for crystal-clear visuals, the versatile MSA Plus SMD LED Screen Module, the sleek MSA Ultra Thin SMD LED Screen Module for modern setups, the durable MSG Outdoor SMD LED Screen Module, and the efficient MSG Indoor SMD LED Screen Module perfect for indoor environments.

We also offer exceptional Outdoor SMD Screens, Indoor SMD Screens, Flexible SMD Screens for creative designs, Cabinet SMD Screens for secure setups, Signpole SMD Screens for advertising, and stunning SMD Video Walls for large-scale visual impact. With SMDLED.PK, experience reliability, superior technology, and tailored solutions for all your display needs. Visit us today and transform your spaces with unparalleled visual excellence!

Contact Us For Free Consultation at 0306-1333384

Powered By BIACommunication